Realizing Creative Inspirations Through Digital Continuity

CO Architects Leverages Generative Design Tools for Continuous Architectural Design & Engineering Innovations

White Paper by Dassault Systèmes

CO Architects focuses on programmatic and engineering requirements to drive artful design solutions, and leverages technology to create innovative, impactful and lasting architecture. While technological innovations expand what is conceptually possible, fundamental obstacles within the design and construction industry threaten to constrain the vision. Fortunately, digital continuity on a central platform helps to overcome fragmentation and enables a seamless process from concept to production-level design. Several recent CO Architects projects demonstrate the exciting potential of generative design powered by the 3DEXPERIENCE platform.

Balancing Programmatic & Aesthetic Expectations

Delivering solutions that meet the life safety and mission-critical needs of today, while planning for the unexpected functions of tomorrow, is no easy feat. Hospitals and laboratories, for example, demand extraordinarily high levels of coordination between architectural design and MEP engineering teams to balance a multitude of air, water, and technology systems. Given that some of the critical technology and equipment that ultimately will go into the building has often not yet been developed, therefore these buildings must be designed to accommodate change—new functions, workflows, and other unforeseen conditions.

These institutional projects must also appeal aesthetically to users and the surrounding communities. CO Architects views programmatic and engineering requirements as drivers for artful design solutions. The firm strives to design buildings that enrich the lives of the people who use them, gracefully fulfill functional and technical expectations, and appeal to the senses as well as to the intellect.

The rolling green roof on Palomar Medical Center provides enhanced views for patients and staff while mimicking the nearby rolling hills. Functionally, its undulations create cavities for ductwork and utilities to run, while the long-span trusses create a column-free floor plate to accommodate future renovations as technologies change. The best design solutions successfully integrate program and function.

CO Architects has committed to pioneering new paths in architectural design using the latest digital technologies. The firm first committed to 100% digital documentation in the mid-1980s and led the industry in adopting BIM-enabled integrated project delivery in the early 2000s. Leadership saw that early adoption of technology enhances the design and delivery process. Solutions such as those from Dassault Systèmes have exponentially improved this process, bringing designer and builder together around shared technologies and creating more efficient, transparent, and collaborative processes. This ultimately results in higher quality, more rapidly delivered, and less costly buildings for clients.

Three Challenges Hold Back Next-Level Innovation

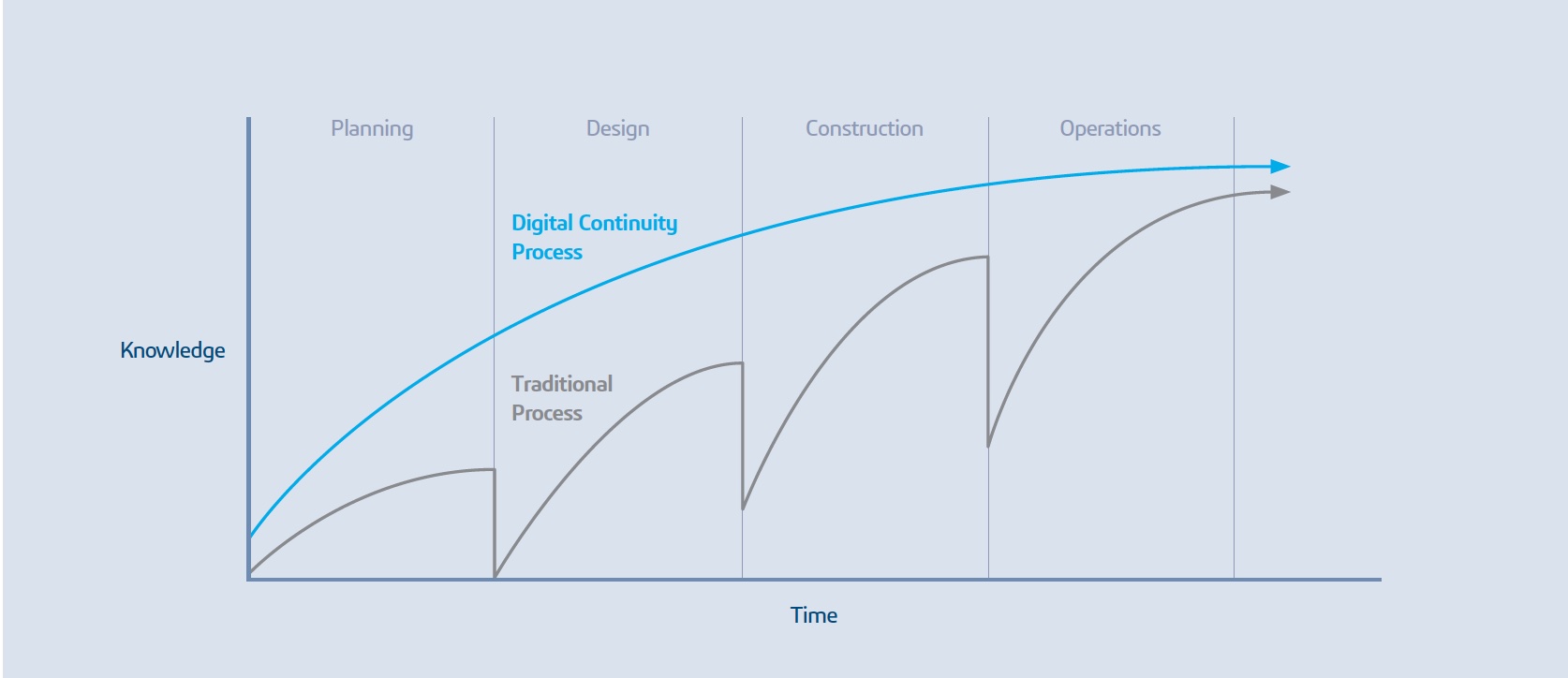

New digital solutions are expanding the limits of what is possible in architecture. But achieving these possibilities is often hampered by traditional approaches. Perhaps the greatest challenge facing the industry today is the fact that the many players involved in bringing a building from concept to operation remain largely siloed. Delivery models have evolved.

Digital tools have become the norm. Yet hurdles remain in the flow of information from design to engineering to fabrication to operation and continue to be a challenge on almost every project. Consider the following universal design and construction industry challenges:

Shifting project responsibilities contribute to lack of project ownership. New project delivery methods seek to gather greater levels of knowledge earlier and throughout the project lifecycle, but dated contractual roles hamper these efforts. Subcontractors are becoming involved early as design partners in design-assist teams, while designers are providing more insight during fabrication and even construction. But these blurring lines are challenging to define. Risk-averse team members too often focus on benefits to their entity over benefits to the project. This lack of project ownership can impact a building’s overall quality and final cost.

Disjointed tools add to inefficiency and waste. Waste has long been a problem for the design and construction industry. Even as new software tools are introduced to make each trade more efficient, the lack of interoperability among these tools leads to a high level of rework and a loss of knowledge in the translation among tools and drawings. At every level there is a translation into the right tool to do the job better: designers use tools to boost early iteration; fabricators use tools to create greater level of detail; owners and permit agencies still expect 2D documents. The architect must recheck documents throughout the process to make sure the design intent is maintained, and correct any mistakes made in translation. The result is extraordinary levels of waste in time and money, as well as loss in data during handoff.

Communication must adapt to meet a range of end-user needs. Architects are tasked with communicating a vision clearly to every project stakeholder. The first step is conveying a design intent that meets the client’s goals. CO Architects’ clients, for example, are often multi-layered, representing multiple segments of their organization from top administrators to facility directors to project managers. Many of these individuals are not accustomed to looking at architectural drawings. Utilizing 3D digital tools and physical representations offers another opportunity to clearly communicate the design intent to this wide range of project stakeholders. Design solutions must also be communicated to builders and contractors in a way that clearly explains the design intent appropriately through documentation. The architect often relies on the contractor’s reproduction of the design as shop drawings to convey back to the designer their understanding of it — a time-consuming exercise.

New Digital Solutions Lead to New Challenges

Today’s computational design solutions have allowed for a new level of complexity in design. Firms like CO Architects use computational design for:

Yet with New Tools Come New Risks

Fragmentation. Some computational design tools help young architects to iterate more rapidly in the early design process. However, the information that is produced tends to be fragmented. Should the designer move on to a new project, the knowledge of what led to certain decisions (or even which version is the appropriate to use) is lost, because that knowledge is not embedded within the model.

Lack of Interoperability. The architect’s contractual responsibility is often to produce a set of drawings, rather than a model or set of geometries. As a result, architects begin working with one tool to create rapid iterations. Then they transfer the information into another tool better suited to produce and manage drawings. From there, information is sent to the fabricator, who will transfer the data into another tool that allows for a high level of detail to machine directly. Moving data between multiple platforms limits the level of information that can be shared. There are ways to transfer information from program to program, but developing those solutions is not easy and takes time. Working with a multitude of models may cause staff to spend an exorbitant amount of time organizing, sharing, and troubleshooting information. In addition, few conceptual design software options are able to deliver a model that can be easily adapted for fabrication processes due to accuracy challenges, compatibility, and geometry limitations.

Too much data? Architects, engineers, contractors and owners all look at project information through different lenses. Some only want information on geometry or quantity or maintenance needs. Providing all project information to each of these parties leads to information-overload. In addition, high levels of detail will affect model performance and, therefore, are often avoided to the detriment of information completeness and efficiency. For example, once design process iteration is purged from the models to improve speed, there is no going back to a previous version, drastically limiting design flexibility.

A Call for Comprehensive Digital Continuity

Efficiency in design and construction depends on better connecting designers with makers. New delivery methods, such as design-build and IPD, are a response to this need, but these new methods must be supported by new tools to see the full benefits desired. A cloud-based platform that provides high-fidelity, live design information to a host of parties, from design through fabrication, allows project stakeholders to control project cost and quality in ways not previously seen in the industry.

As projects progress, the number of people involved in the decision-making process increases. Institutional projects already begin with a multi-layered set of stakeholders. Adding in specialty engineering disciplines, general and trade contractors, fabricators, suppliers and installers, the number of team members grows rapidly. Likewise, the risks of diluting the original goals and relinquishing individual responsibility grow. At every handoff to a different discipline and every switch in deliverable medium — whether shop drawing, fabrication model mock-up, or other — the risk of a departure from the design intent increases.

Digital continuity allows for the clear communication of the project goals, vision and intended execution throughout the process to ensure everyone involved understands what they are working towards and need to ultimately achieve.

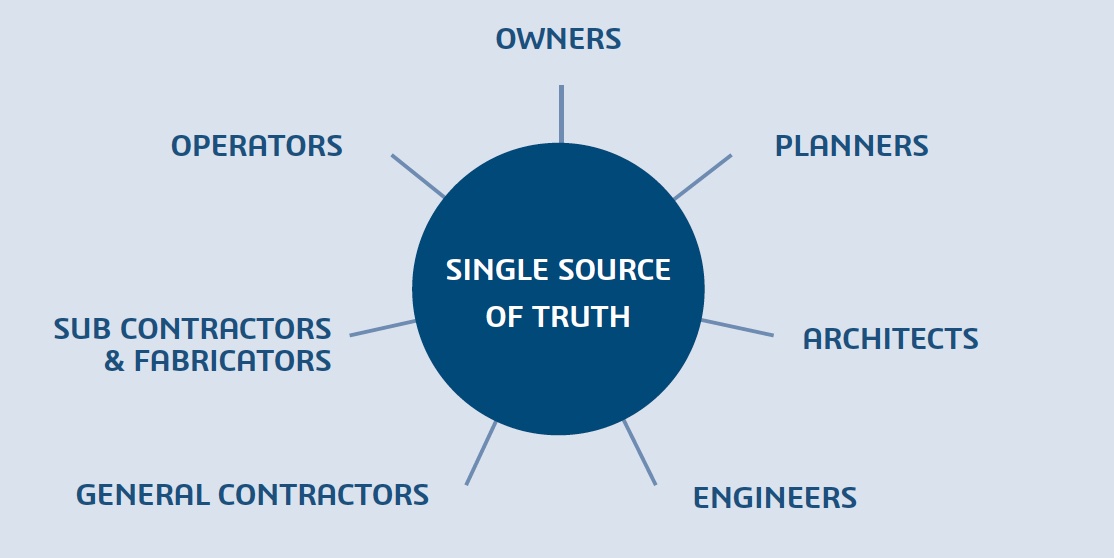

The 3DEXPERIENCE platform, for example, allows the entire design and construction ecosystem to share the same model. With no one working in complete isolation and everyone using the same data, the inherent inefficiencies that happen though rework are averted. The 3DEXPERIENCE platform minimizes re-drawing and re-modeling and reduces the potential for reinterpretation of the design intent or the generation of iterative cycles in isolation. It supports a continuously evolving and flexible environment that remains nimble and is able to absorb change, saving time and providing a more effective and innovative outcome.

A Central Repository for Project Knowledge

Given the extensive amount of information and collective knowledge it takes to create buildings, the digital model on the 3DEXPERIENCE platform essentially becomes a central repository that includes information about project goals, decisions, parameters and the evolution of solutions. Everyone sees the same data and contributes to a truly integrated project repository. They immediately and collectively evaluate the impact of changes on project goals.

A central repository allows the input of material, system, fabrication or installation parameters as early as possible, leading to more intelligent design. By applying installation limitations early in the process, there are fewer adjustments during construction—adjustments which are costly and may negatively impact building occupants.

This approach also mirrors the non-linear method by which most construction projects are delivered today. For example, laser scanning during construction can feed as-built data back into the model to determine if details need to be adjusted in order to account for elements out of tolerance. Having fabrication knowledge during the design phase helps minimize material waste, reducing both cost and impact on the environment.

Adoption of the 3DEXPERIENCE platform nurtures trust, open minds and a willingness among the complete project team to share responsibility—an antidote to the risk-averse and litigious nature of the construction industry.

For the OHSU Collaborative Life Sciences Building & Skourtes Tower in Portland, OR, CO Architects provided the complete metal panel layout for the compound angled surfaces. The fabricator took the model and surface development and used it to directly generate the shop drawings and panels.

Introducing 3D Generative Innovator

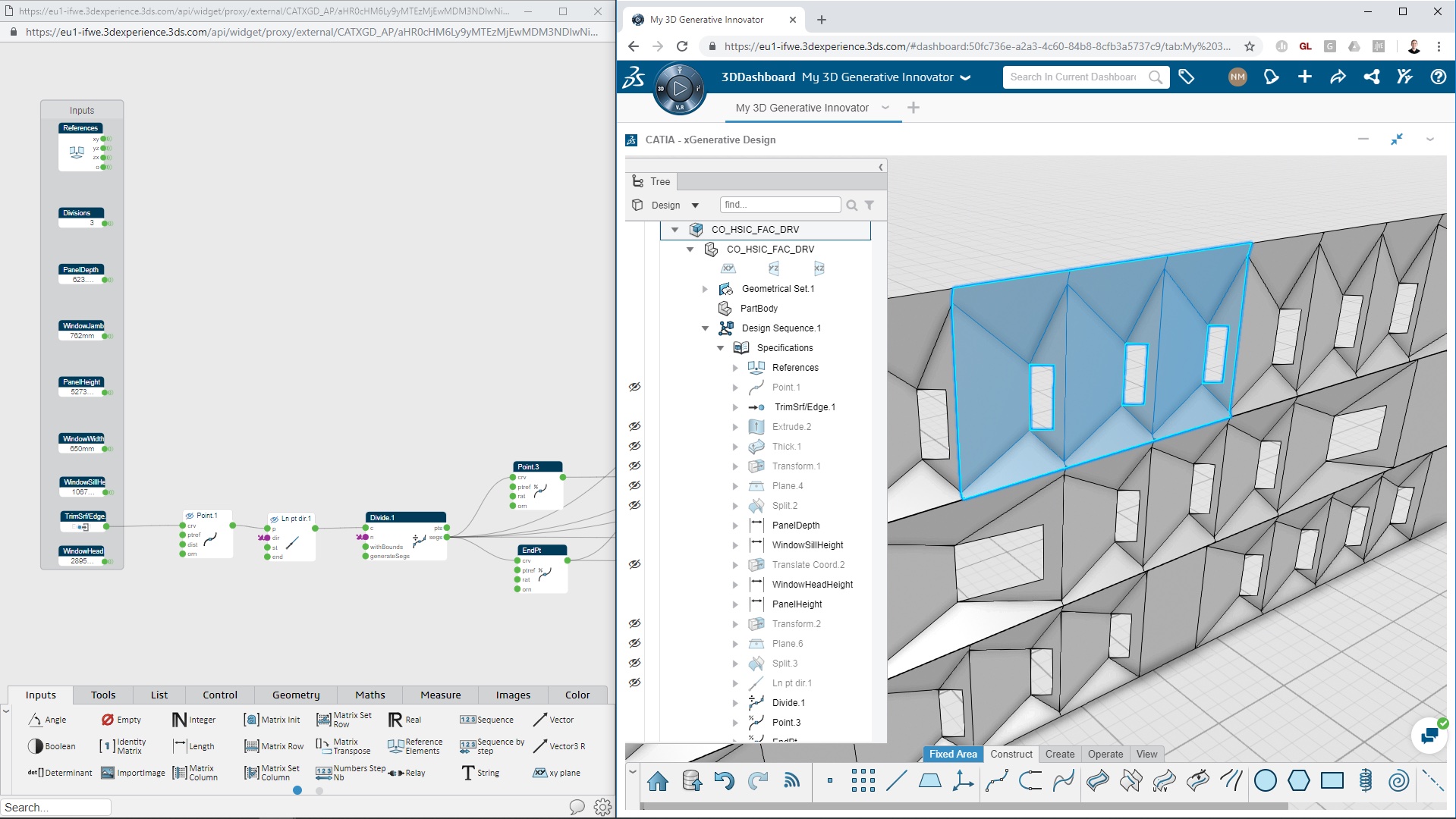

The 3D Generative Innovator role enables a continuous Level of Development that seamlessly connects the conceptual design model with the fabrication model. It supports architects in designing, exploring and validating variants of complex, repetitive, and non-regular shapes and patterns with an intuitive algorithmic approach.

The software takes a unique approach in developing architectural geometry. Unlike traditional solutions for visual scripting, it does not require designers to immediately immerse themselves in the world of nodes and connections. Instead, designers can begin modeling elements directly in a familiar 3D view. A few clicks reveal the logic underneath. From there, designers can layer more intricate rules that extend the original model’s driving principles. This ability to layer and extend design logic from conceptual design and beyond is a powerful tool for adding intelligence to complex concepts.

The 3D Generative Innovator role takes a powerful parametric design technology and presents it in a clean, easy-to-understand format. This means that architects can spend more time establishing important relationships in their designs while spending less time “programming” the solution.

Simple, accessible solution. The xGenerative Design application within the 3D Generative Innovator role is virtually instantaneous to get up-and-running. Because it is a browser-based cloud solution, there is no need to install code, manage files, or be tied to a high-end CAD workstation. The program can run on any device, from anywhere, and at any time. Designers can take it with them to visit partners, fabricators, and clients. Moreover, users can receive design updates by simply refreshing the browser.

Instant understanding of design changes. CO Architects’ complex healthcare and laboratory projects require a rigorous space planning process, which has pushed the firm to seek ways to drive the composition of building program space through more automated means. Every change to building massing, location and other factors impacts the total project cost. By automatically updating the cost impact as a result of changes, there are no surprise cost overruns at the project end. While the firm had explored ways to animate the change in cost visually through parametric models, the 3D Generative Innovator role simplifies this process. And being a cloud-based solution, the architect can easily and instantly share the real-time cost impacts of design changes with clients.

The Health Solutions Innovation Center at Arizona State University features a trapezoidal undulating façade that was designed to minimize the solar exposure of the glass on the east and west facades. Working within a set of specific constraints, 3D Generative Innovator provided the crucial design tools CO Architects needed to rapidly test various configurations of the primary surfaces and basic structural framework to validate the design intent and required clearances for the envelope. Because it lives within the same ecosystem as CATIA, the designers were then able to launch into more detailed parametric 3D design, allowing them to go back and forth in levels of detail, all within a single environment.

The Future of Architectural Design

Iterative conceptual design functionality and integrated digital fabrication are hallmarks of the future of architectural design and construction. The industry is refocusing efforts away from documentation and rework, towards design innovation, leveraging craft and expert knowledge, and operational flexibility. CO Architects envisions infinite outcomes achievable through a seamless process from concept to production-level design. This unlimited creativity is driven by the 3D Generative Innovator role.