UCLA Rosenfeld Design Development

COworkers explain the design process of UCLA Rosenfeld Hall after reaching a design milestone. Take a look through a series of gifs and images to learn how the design team creatively reviews design options with UCLA to understand all the nuances of the project in real-time.

By Xinhao Li, Jen Wong and Tanner Clapham

UCLA Rosenfeld DD Milestone: Part 1 - Design Explorations

Through the design process of UCLA's Rosenfeld Hall, the team took advantage of both physical models and renderings to improve the team’s abilities to evaluate and discuss the strengths and weaknesses of different design strategies.

Rosenfeld Hall will consolidate a variety of surgical training, simulation and standardized patient programs into a single facility through a combination of renovation and building addition to an existing facility. The 1976 two-story building was designed by Daniel Dworsky, originally as a laboratory facility with a roof garden and terrace. In 1994, a steel-framed barrel-vault student lounge was added on top of the existing roof terrace – now referred to as Level 2. The scope of this project includes a gut renovation of Level 1 to enhance the existing simulation center and standardized patient suite and the construction of a new rooftop addition on Level 2 to host the Center for Advanced Surgical and Interventional Technology (CASIT).

The dominant material of the building is board-formed concrete with a vertically oriented texture, which possesses an honest expression of construction techniques and withstands time without degradation. In contrast to the character of the existing building, the addition is conceptually a light-touch on the existing heavy base. Carefully articulated atop the concrete structure, the new structure is differentiated through transparency, warmth and subtlety. Reinforcing the original building’s strong horizontality, a razor-thin roof hovers over the new and existing alike, creating a unified architectural expression that stands in stark contrast to the towering pine trees that surround the site.

The intricacies and nuance of the unique existing structure provided CO with an opportunity to leverage physical model making as the primary tool for the design process. The design team used the physical model – not only to test various approaches and evaluate against the existing context of the building expansion both in form and material – but also to present the design strategies to clients more comprehensively. For the CD phase, the team will explore the potential of physical model at a larger scale to get a more comprehensive understanding of this project as it relates to construction detailing and materiality.

The GIFs and renderings demonstrate a series of design explorations that were presented during the schematic design phase. Through conversations with UCLA stakeholders, it was agreed to pursue the “plane” scheme with some integration of the “veil” concept potentially incorporated into the architectural expression. Rather than a few static views of the project through renderings, these models helped the design team and UCLA understand all the nuances of the project in real-time; the team could review all the ins and outs of the project holistically.

The GIFs showcase how different buffer conditions integrate with the design. On the west and south sides of the lab, a gallery space and renovated lobby with a new skylight serve as the buffer area. Wood material and linear expression of gallery wall, vertical mullions and ceiling slats bridge the materiality between new addition and existing board-formed concrete building.

UCLA Rosenfeld DD Milestone: Part 2 – Space Types

PROGRAMMATIC STACK

The existing simulation program on Level A will remain operational during construction. Level 1 will be almost a full gut, while Level 2 will involve gutting the existing barrel vault and removing the concrete planters and brick pavers on the walkable courtyard roof to reduce the weight of the upper level and allow for the expansion without triggering any structural retrofits.

Level 1 will feature a standardized patient suite, accompanied with four medical / group simulation labs, 60-person classroom, debrief room and workplace. Level 2 collocates the Department of Surgery’s CASIT education lab and research & design lab with their associated workplace environments.

Here are a couple space types and design constraints CO explored in the SD and DD phases:

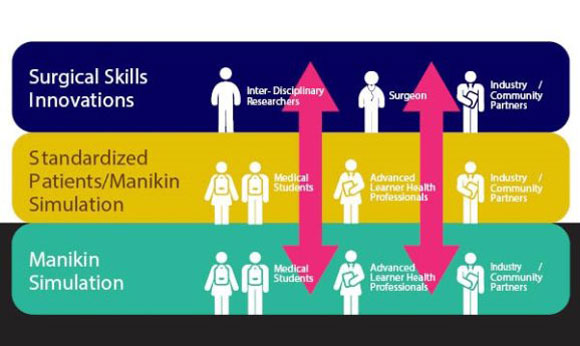

CASIT EDUCATION LAB

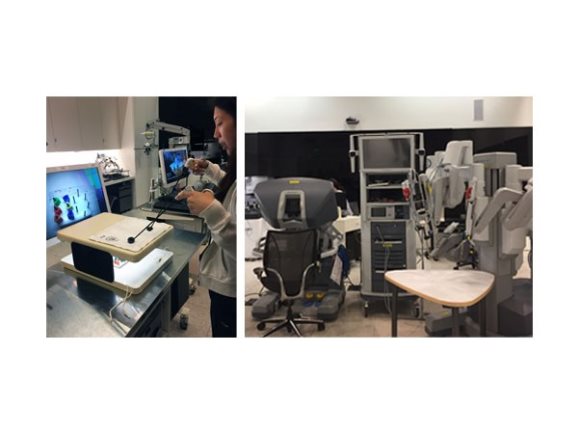

The education lab will be the main feature of the building and centrally located on Level 2. The education lab will be located inboard to limit and control the amount of daylight and sound entering the room. It will house up to 20 lab stations and have maximum flexibility in surgical training and other activities. During the design process, the design team had the opportunity to try one of the OBGYN surgical training exercises. Surgical training also includes using innovative tools such as the Da Vinci System – a system used for “robotic-assisted surgery” and the main driver of certain clearances and standards for the space – down to the width of the elevator doors. CO watched the CASIT Director Dr. Dutson perform a surgical procedure on a patient where he used the Da Vinci System and broadcasted it to the existing education lab from Reagan Hospital to allow researchers and engineers to observe and understand how the surgical tools are used and find ways to improve them.

Through multiple iterations, CO worked with the CASIT team to provide a state-of-the-art technology display on the west wall that allows instructors to communicate with other labs and the hospital. The north wall will have a smaller technology display that can be used if the room is divided into two by a vertical operable partition. There was extensive coordination between structural, AV/IT, acoustics and architecture team members to create a flexible room that can be used as one large instruction space or divided in two for simultaneous instruction. The design will incorporate a regular spacing of power and data floor boxes to allow for a range of layouts and use.

CASIT RESEARCH & DESIGN LAB

The research & development lab will have multidisciplinary uses. The current facility is one large lab with several stations for 3D prototyping and fabrication. The future space will be set up as a "maker space" with zones to accommodate different types of research projects. One of these zones will have an enclosed room with dedicated exhaust, another will require an area protected from light for laser use. In its current formation, the lab is devoid of any partitions. CO worked with the client to develop a 6’ module to allow the flexibility needed for the PhD students who are working on different experiments and research.

MEDICAL SIMULATION ROOMS

The medical simulation rooms will provide the flexibility to serve interdisciplinary simulation needs and a broad learner base. The rooms will be equipped with functioning headwalls with compressed air and vacuum to mimic hospital settings. Instead of actors posing as patients, manikins hooked up to the headwalls will be used. These rooms will also be monitored with cameras, microphones, speakers and full-length one-way glass facing the corridor to increase transparency.

STANDARDIZED PATIENT SIZE - BULLPEN

The standardized patient suite will be adjacent to the medical simulation suite, so that both spaces can be utilized simultaneously. Having the SP suites in this building encourages synergies with the existing simulation center on Level A and encourages opportunities for collaboration and curriculum. The suite will be arranged in a “bullpen” layout, which segregates the circulation systems of the patient actors and students.

It is in best interest to keep the SP exam rooms consistent and mimic the health stations at their own hospital. Cameras, microphones, speakers and one-way mirrors are part of each SP exam rooms so the instruction taking place can be recorded and observed from a monitoring room.

It has been an exciting process and the design team looks forward to sharing the developments and take a deeper dive into the intricacies and construction details.